Motor-driven pump

The motor-driven pump allows the length and stroke frequency to be adjusted according to the speed of the pump motor.

VARIO and SIGMA motor pumps are used for dosing chemicals such as disinfectants, flocculants or additives… up to more than 1000 l/h.

They are used for the treatment of drinking water, cooling towers, waste water, industrial processes, swimming pools with electrolysers….

DOWNLOAD

Notices techniques VARIO

Notices techniques SIGMA

Plaquettes commerciales

Motor-driven pump – VARIO

The VARIO range ensures a high accuracy of chemical dosing.

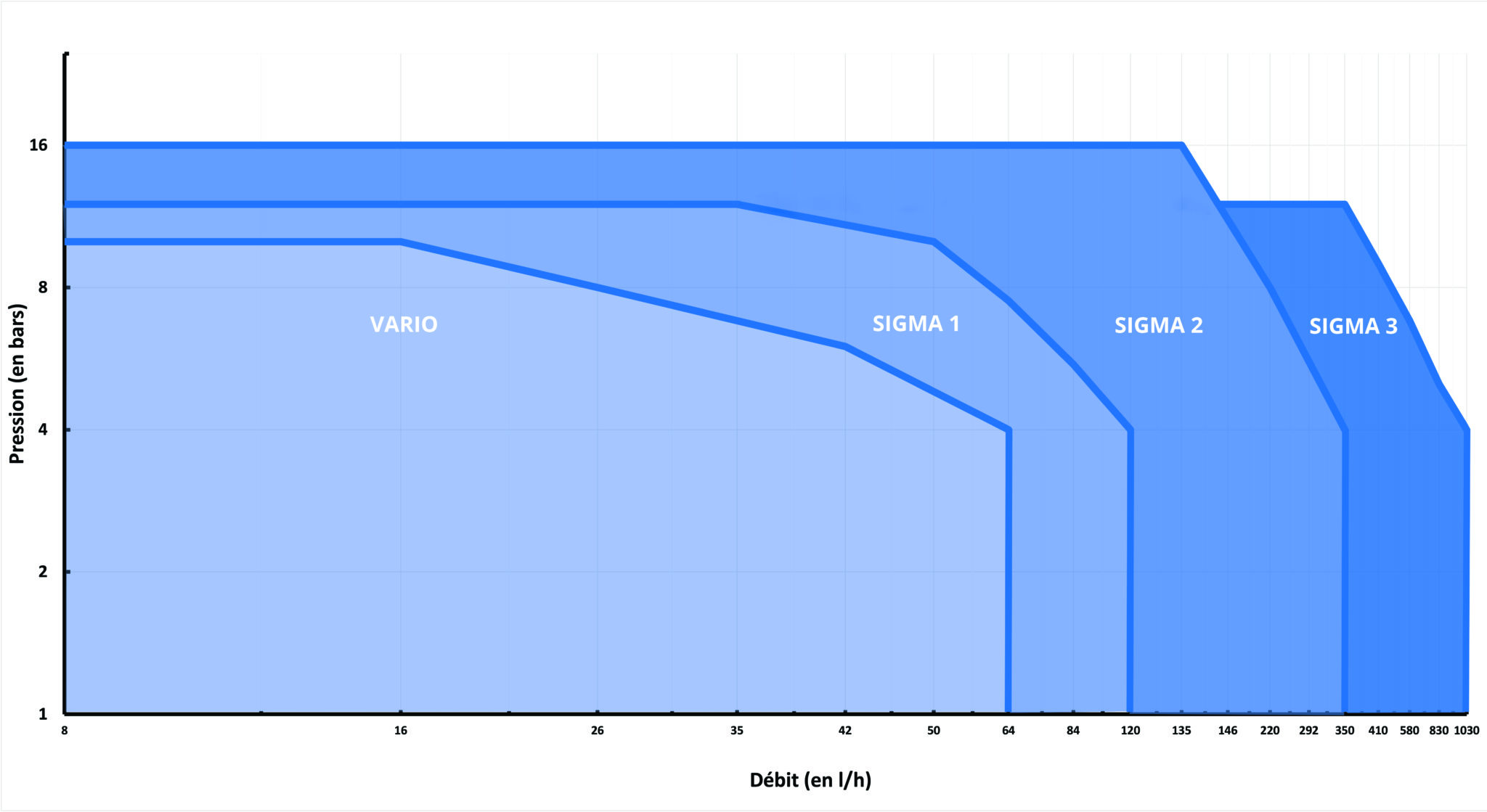

- Range of flow rates from 8 to 64 l/h with pressures from 10 to 4 bar,

- High precision in the dosing process even with fluctuating pressure ratios,

- Flexible regulation of the membrane stroke lengths…

Technical features:

- Flow range from 8 to 64 l/h

- From 10 to 4 bar

Motor-driven pump – SIGMA

The SIGMA motor-driven dosing pump consists of 2 versions :

– the basic version

– the version with intelligence including a removable control unit (optional control module with 4-20 mA outputs, analog controls, fault outputs and various control variants as standard)

These 2 versions are also divided into 3 categories classified according to their flow ranges:

- Sigma/ 1 with a flow rate ranging from 17 to 120 l/h and from 12 to 4 bars

- Sigma/ 2 with a flow rate of 50 to 350 l/h and 16 to 4 bars

- Sigma/ 3 with a flow rate of 146 to 1030 l/h and 12 to 4 bars

The advantages of SIGMA pumps

The SIGMA range has many advantages such as :

- The guarantee of a secure process thanks to a multilayer membrane with visual rupture warning or contact (optional),

- An air purge,

- Servomotors or servo drives for the adjustment of the motor rotation frequency,

- 2 standard materials PVDF/PTFE, stainless steel/PTFE …

Technical features:

- SIGMA 1 : from 17 to 120 l/h and from 12 to 4 bars

- SIGMA 2 : from 50 to 350 l/h and from 16 to 4 bars

- SIGMA 3 : from 146 to 1 030 l/h and from 12 to 4 bars

TECHNICAL FEATURES

Material

- PPE : Polypropylene Head – Polypropylene Valve – EPDM Seal

- PPB: Polypropylene Head – Polypropylene Valve – FPM Seal (Viton)

- PPT: Polypropylene Head – PVDF Valve – PTFE Seal

- NPE : Acrylic Glass Head – PVC Valve – EPDM Seal

- NPB: Acrylic Glass Head – PVC Valve – FPM Seal (Viton)

- NPT: Acrylic Glass Head – PVDF Valve – PTFE Seal

- PVT: PVDF Head – PVDF Valve – PTFE Seal

- PCB : PVC head – PVC valve – FPM Seal (Viton)

We are here to support you …

Do you have any questions? Need a diagnosis, recommendations? Need a documentation, an estimate ? The SYCLOPE team is at your disposal …